Questions and answers on the subject of eyewear protection

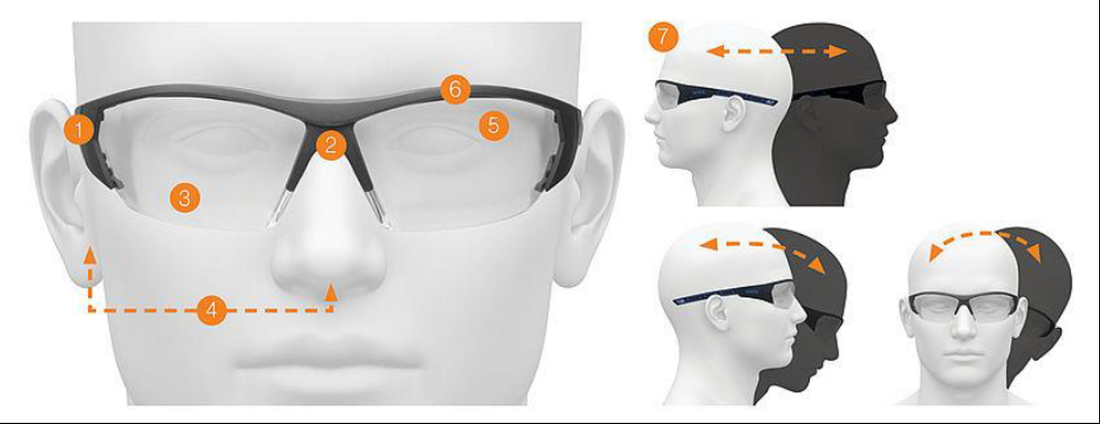

We recommend the following 7 steps to check whether your safety glasses are sitting properly:

- You shouldn’t be able to feel any uncomfortable pressure points at the side of your head and behind your ears

- The nose pad should be comfortable and sit on the nose without pinching

- You should be able to see clearly and have an unrestricted view in all directions

- The total weight of the safety glasses should be evenly distributed between your ears and nose so that the frame sits comfortably on your face without distracting you from the tasks you have to carry out

- The frame or lens should sit close to your face without touching your eyelashes. The gap between the lens and your face should be narrower than a pen (<=6-8mm)

- The frame or lens should cover the eyebrows and all other soft areas

- The glasses should sit firmly on your head when you move your head in all direction

We recommend storing your safety glasses in their original packaging in a dark, dry place, where the product will not be subjected to mechanical loads, the temperature is below 40°C and air humidity is below 70%. If stored correctly, the safety glasses will have a shelf life of six years from the date of manufacture. The date of manufacture is shown in clock format (the arrow accompanied by the last two digits of the year points towards the month of manufacture) or factory icon (month/year) on the safety glasses and their packaging.

The service life of a pair of glasses depends on the workplace environment and the way in which they are handled at the workplace and cannot therefore be determined on a general basis. The recommended service life is a maximum of two years from first use, depending on the intensity of use, frequency of use and wear caused by external factors; the date of first use should be recorded.

We recommend the following method for cleaning and disinfecting uvex safety glasses:

- Read the information in the instructions provided with the safety glasses

- First clean the glasses under running water. Standard cleaning agents can be used

- If necessary, uvex safety glasses can also be cleaned by disinfectant wipes or sprays. Do not clean the glasses by soaking them in disinfectant. Read the instructions for your chosen disinfectant and clean the glasses in accordance with the instructions with regards to usability, disinfection process and exposure time. If indicated in the instructions for the disinfectant, rinse thoroughly using fresh water afterwards

- Allow to air dry

- Check the respective glasses for any damage after each cleaning cycle and before using them again. Stop using the glasses if you notice any signs of damage

We recommend the following approach for cleaning and disinfecting uvex safety glasses after coming into contact with viruses:

- Read the information on the instructions provided with your safety glasses.

- During cleaning, we recommended wearing disposable gloves made from nitrile or latex.

- First clean the glasses under running water.

- uvex safety glasses can also be cleaned with disinfectant wipes or sprays. Do not clean the glasses by soaking them in disinfectant. Read the instructions for your chosen disinfectant and clean the glasses in accordance with the instructions with regards to usability, disinfection process and exposure time. If indicated in the instructions for the disinfectant, rinse thoroughly using fresh water afterwards.

- Allow to air dry in a non-contaminated area.

Please note that uvex has not tested which disinfectant has an anti-viral effect, nor which is best-suited to the respective uvex product. Some of the recommendations made by the Robert Koch Institute apply to anti-viral disinfectants. Prolonged contact time, frequent use of disinfectant products or high drying temperatures can damage the coatings and other components of the glasses. As a user, you must check the glasses for damage after each cleaning cycle and before using them again. Stop using the glasses if you notice any signs of damage.

We recommend that you do not use silicone-based cleaning agents to clean our safety glasses. These can attack the coating, which may result in the anti-fog property being lost. There is also a risk of a deposits forming on the coatings. However, it is possible to also clean them using all standard cleaning agents or soap and water.

uvex recommends wearing full-vision goggles where either tightly sealed safety glasses need to be worn to protect the eyes against hazards, or where there is a risk of fast flying particles causing safety spectacles to fly off your head. This means, for example, when using Flex angle grinders, general angle grinding, working in dusty conditions, or when handling dangerous substances such as chemicals. However, it is always advisable in individual cases to have a safety specialist or safety authority carry out a safety assessment.

In general, the level of resistance offered by our coatings always depends on the chemical being used. Please feel free to contact our customer service team, who can provide you with more detailed information about the chemical you are using.

There are no defined tests for resistance against chemicals set out in the EN166 standard, as is the case with chemical protective gloves, for example. In principle, all uvex safety glasses offer a first barrier of resistance against chemicals. Depending on the chemical, however, the mechanical strength of the safety glasses may have been affected after contact. The lens material may also become cloudy and therefore no longer be able to guarantee full visibility. uvex therefore recommends that you clean the safety glasses immediately after contact with light chemicals and dispose of the glasses after contact with dangerous chemicals and use new glasses. Incidentally, this is also the case with chemical protective gloves.

In general, all our glasses are able to withstand temperatures of up to 80°C as far as the material is concerned. However, the following additional points need to be taken into account:

- Mechanical strength (if a T marker is present) is only guaranteed up to a temperature of + 55°C. Resistance beyond this has not been tested.

- Infrared radiation may also occur at high working temperatures, depending on the area of work. In this case, welding protection would be necessary.

- It is possible that at high temperatures, the entire face must/should be protected, i.e. a visor is used.

- Our uvex full-vision goggles are available with polycarbonate (PC) as well as cellulose acetate (CA) lenses. It should be noted that the CA material begins to warp at temperatures of +80°C. PC material, on the other hand, retains its shape.

We will be happy to advise you if you are unsure whether the glasses you are using will withstand the temperature of your workplace or whether you are using the right glasses. Please do not hesitate to contact our customer service team.

uvex occupational safety glasses comply with the environmental principles of the uvex group in compliance with the EU REACH chemicals regulation.

uvex occupational safety glasses are free from substances that destroy paintwork such as silicone* or latex**.

*This excludes Item 9302500 uvex ultrasonic CR, which has a silicone headband.

** All rubber woven straps contain a very small proportion of rubber threads (latex). These are needed to keep the band elasticated, but do not come into direct contact with skin.

uvex safety glasses with polycarbonate (PC) lenses guarantee 100% UV protection up to 400 nm.

uvex safety glasses with cellulose acetate (CA) lenses guarantee UV protection up to 380 nm.

uvex safety glasses with hard glass (HG) lenses guarantee UV protection up to 330 nm.

They therefore offer the wearer protection against UVA, UVB and UVC radiation.

UVA radiation: 315 nm – 380 nm

UVB radiation: 280 nm – 315 nm

UVC radiation: 100 nm – 280 nm

The first digits on the lens marking represent, on the one hand, the respective protection in accordance with the various standards, and on the other hand, the level of light transmission through the lens, i.e. the type and characteristics of the tinted lens. In the table shown, we have provided you with a brief overview of what the individual lens markings mean:

| Lens marker | Protection against | EN standard | Explanation |

|---|---|---|---|

| 2 | UV | EN 170 | Number 2 indicates that the filter may impair colour recognition. |

| 2C or 3 | UV | EN 170 | The number 2C indicates that the filter allows for good colour recognition. |

| 4 | IR | EN 171 | Protection against heat |

| 5 | Sun / glare | EN 172 | 100% UV sun protection - without infrared (IR) protection. |

| 6 | Sun / glare | EN 172 | 100% UV sun protection - with infrared (IR) protection. |

| Marker | Transmission |

|---|---|

| 1.2 | Permits more than 74.4% light transmission but less than 100%. |

| 1.4 | Permits more than 65% light transmission, reduces blue light by 50%. |

| 1.7 | Permits more than 43.2% light transmission but less than 58.1%. |

| 2.5 | Permits more than 17.8% light transmission but less than 29.1%. |

| 3.1 | Permits more than 8.0% light transmission but less than 17.8%. |

The search for suitable disinfection measures has vastly accelerated in recent weeks in order to effectively contain the spread of coronavirus. A new method is disinfection by means of UV radiation (UVC lamps). To this end, we are now increasingly receiving inquiries about which personal protective equipment (PPE) should be used during this type of disinfection.

Risks presented by UV lamps

UVC rays are the most energy-rich UV rays and do not reach our Earth's surface in their natural form, the sun's radiation. In an artificial form, for example through lamps, UVC radiation can lead to the eyes being dazzled, skin redness and an increased risk of skin cancer. Furthermore, UVC lamps of this kind can also be very bright and emit a high, energy-rich and visible blue light, for which there is a well-founded suspicion that it promotes retinal detachment (macular degeneration). For these reasons, safety measures must be taken during use.

Safety measures

In the event that it is not possible to keep the activated UVC lamp away from the human body, it is recommended that you wear something that protects both your eyes and face in addition to wearing appropriate UV protective clothing for the body and hands. This should consist of a visor (in accordance with EN166 and EN170) to protect the skin on your face and eyes from UV radiation. If there is a risk of glare and/or strong blue light emission from the lamp, check whether it is also necessary to wear safety glasses with a very dark tint to protect against glare. One option in this case would be to wear level 3 to 5 welding safety glasses in accordance with EN169.

The following uvex face and eye protection products meet the above criteria:

Visor:

uvex pheos visor face guard 9790211

uvex face protection 9707014, 9708514, 9705014 or 9706514

In combination with the following glasses:

uvex i-vo welding safety glasses 9160043, 9160045

uvex super fit welding safety glasses 9178043

uvex astrospec 2.0 welding safety glasses 9164143, 9164144, 9164145

uvex futura welding safety glasses 9180143, 9180144, 9180145

uvex 9116 welding safety glasses 9116043, 9116044, 9116045

uvex 9161 welding safety glasses 9161143, 9161144, 9161145

uvex super f OTG welding safety glasses 9169543, 9169545

Important information:

"Disposable visors" that are currently available for sale on the market and which are not labelled in accordance with EN166 do not generally offer sufficient UV protection across the entire UV spectrum and are therefore not suitable for this type of use.

UV disinfection of uvex PPE can lead to degradation of the material properties and thus premature ageing and damage, limiting the protective effect of the product. We therefore do not recommend using UV lamps to disinfect our eye protection products. For more information about the recommended cleaning and disinfection of our safety glasses, please refer to our letter that provides information about the use of safety glasses when coming into contact with the COVID-19 virus.

Please also note that due to the many different UVC lamps on the market, it is not possible for us to provide a general recommendation or exposure period for all lamps. A safety assessment must always be carried out in individual cases by a safety specialist or safety authority.

If you are uncertain about anything or have any questions, please contact your relevant uvex sales contact.

The main information here comes from sources from the International Commission on Illumination (CIE), which you can see in detail here:

German

English